If you think boots are too “country” or “cowboy” or “casual” – not to mention taboo for business – it’s time to catch up. You’re now as likely to see cowboy boots in a corporate suite as at the Mesquite rodeo.

Boots arc a multi-million dollar business in Texas alone, with comparable sales in the other Southwestern states. There’s a new breed of customer in Texas – the white collar professional who wants boots for looks more than for wear and will pay for what he or she thinks looks good. Only about 20 percent of buyers are women, but the percentage is increasing. The market, retailers say, is still virtually untouched.

Styles are as varied as prices. You can spend as little as $35 for a pair of simple cowhide boots, but the leather may be stiff and difficult to break in, and you’ll surely regret trying to go “cheap.” A good work boot averages $75 to $100. The fastest-growing category of boots in the business, the “exotics,” begin at $100. Exotics are boots made of leather that is, shall we say, unusual: water buffalo, elephant, iguana, horned toad, sea turtle, boa constrictor, anaconda, kangaroo, armadillo, aardvark, ostrich, badger, lizard, antelope, and, the top of the line, alligator. A pair of alligator boots – totally alligator, not just the tops or the vamps (fronts) – costs about $1300. The price is high because American hides are available only from government kills, and the stock from the latest U. S. alligator kill is nearly exhausted.

You can order virtually any boot you want from a private bootmaker or a boot manufacturer. A Houston businessman paid $10,000 for a pair decorated with 110 diamonds, 80 rubies, and four star sapphires. Former President Johnson had a pair with the presidential seal inlaid. Bum Phillips, coach of the Houston Oilers, has a pair of anteater boots (one of his 15 pairs of Sanders boots) dyed powder blue to match the Oilers’ uniforms. A New York model custom-ordered a pair of boots from Cutter Bill’s with pink lops, purple bottoms, decorations of comets, stars, lightning, and planets, and her name inlaid up the sides.

Gene Radcliffe, a Dallas auctioneer, owns $10,000 worth of boots, all custom-ordered from Tony Lama and Lucchese. He’s been Wearing boots for six years, primarily as a trademark. “I’ve got every exotic ever made: rock python, unborn ocelot, sharkskin. I only wear full-type boots, all the same leather.”

His latest boot purchases are a pair of alligator and a pair of gold-colored ostrich. But the most renowned of Rad-cliffe’s collection is his pair of 14-carat gold-plated anteaters; they cost $2000. The polish i$ another $100 a bottle (it contains gold powder).

The biggest retailers in Dallas for western boots are the traditional western wear stores, such as Shepler’s, Cutter Bill’s, Murfy’s, Morgan’s, Well’s, Lus-key’s, Boot Barn, and Boot Country. Dallas stores include B-Bar-B Western Outfitters, Albert’s Western Wear, J D Ranch, Cooper’s Western Wear, Longhorn Ranchwear, Leddy Bros, D-Bar-D Western Wear, and many others. In fact, it seems that every other intersection in Dallas has a boot store or western wear shop. If you’re from out of town, Long-horn Ranchwear will give you a free ride from your motel or the airport to their store for a look without obligation.

According to John English, manager of Cooper’s Western Wear store in Valley View Center, boots are the store’s biggest seller, about 30 percent of overall inventory. “A lot of people we deal with want them largely for style,” he said. Customers are mostly businessmen, bankers, lawyers, and tourists. Most want a natural-tone leather, nothing loud. The biggest market is for natural brown cowhide.

Special events, especially rodeos, help retail sales. During the “big three” (Fort Worth Southwestern Exposition and Fat Stock Show, Cowtown Rodeo, and Mes-quite Chatnpionship Rodeo), cowboy boots on the streets outnumber any other footwear. English says business increases 50 percent during the stock shows. “It’s bigger than Christmas.”

Tom Potter, buyer for Shepler’s in Arlington, says the Dallas boot market, and the Texas market as a whole, is “primarily for the masses. . . .We have people come in here from California and New York and buy boots like crazy. Some people buy 12 pairs at a time.” Shepler’s stocks 25,000 pairs of boots, including some non-western styles, and displays about 6500. Widths on hand range from AAA to EEE. “I’m sure sales will go up a substantial percentage next year,” Potter said. “Higher tops are more and more popular. Heels haven’t changed that much. Toes are not as extreme. Earth colors are big.”

A size 19-and-a-half boot sits prominently in the boot department at Peter’s Boots in Fort Worth. “We can fit 95 percent of the people who come in here,” says manager Whitey Hanson. “We’ve built a reputation on integrity and honesty. If a customer helps us, we guarantee a fit. If he buys a boot and wears it on the carpet, he can bring it back if it doesn’t fit. We have very, very few returns.” Customers include students, tourists, local businessmen, and ranchers.

Other major retailers include the men’s and women’s stores and the major department stores. Neiman-Marcus does a thriving business in boots. Neiman’s customers are mostly ranchers, businessmen, executives, professionals, and tourists who want leather boots and some exotics, though entertainers, athletes, and even ambassadors patronize the store when in town, says boots salesperson Mimi Philbrook.

Neil Turner at Sanger-Harris says his stores sell about 20,000 pairs of boots a year. “We ship all over the United States, because we get so many requests to do so,” he said. “Businessmen and would-be cowboys” are his biggest customers these days.

Western wear dealers are gradually being joined in the boot business by the chrome-and-glass boutiques and fashion salons that nary a cowboy would dream of entering.

Famous designers Fiorucci and Ralph Lauren have added boots and western wear to their lines. “It’s not fashion, it’s life,” insists Lauren, who while traveling out West last year in search of cowboy clothes found none he liked and decided to create his own. Lauren sees his customers as being “into jogging, hiking, farming, riding – pioneering,” and sharing his “feeling for land and openness, want ing natural, rugged, unstiff clothes that look better and better with wear.

“This is not a costumey look,” he says. “It’s not Dale Evans-Roy Rogers; I wanted to capture the classical, romantic look of Gary Cooper.”

And, of course, Sears Roebuck sells cowboy boots. One Dallas Sears branch carries a few Justin boots, one of the most popular brands, and a larger selection of Sears brand boots, which, according to a sales clerk, are made mostly by the Texas Boot Company. The Justin boots are priced as high as $100; the Sears brand are in the $35 to $50 range.

Before you go on a boot binge, there are several things to know about categories and brands. Boots are classified generally according to price and quality.

Low priced: Acme, Wrangler, Cow-town, Texas, and Durango range from $35 to $75, although some styles may be higher. The boots are machine-lasted; that is, leather is stretched by machine across a mold to shape the foot of the boot. Lower grade leather is used. Frye, not traditionally a cowboy boot company, now markets a boot in this category.

Medium priced: Tony Lama, Justin, and Nocona (the big three of the industry); Larry Mahan (Hyer), Sanders, Dan Post. Prices range from $60 to $150, although they are going up; a medium range exotic may cost much more.

The Tony Lama company was begun as a boot repair business in El Paso in 1911 by Tony Lama, Sr. It now turns out 3200 pairs of boots a day and grossed $36 million in fiscal 1978. The Justin Boot Company got its start in 1897, when “Daddy Joe” Justin started making boots for cowboys in Spanish Fort, Texas. In 1890 he moved his business to Nocona, Texas; in 1925, his sons moved the company to Fort Worth. Daddy Joe’s little girl Enid, now 85, stayed behind and started the Nocona Boot Company, which has grown to be the third largest in the country.

The 12-year-old Sanders Boot Company in El Paso turns out 500 pairs a day. Sanders boots are marketed in the West. The company offers its buyers the chance to design boots for retail sale. Norman Salomi of Sanders explains, “We have basic styles, but most retailers will design their boots, the toe and the stitching and maybe the length of the top, for their area.”

Leather in this class of boots is better than in the lower-priced boots and the boots are hand-lasted – wet leather is stretched by hand rather than by machine. “Hand-crafted” means that part of the work on the boot, but not all, was done by hand.

QUALITY BOOTS: These are made largely by hand by master craftsmen and carry names that are renowned throughout the boot-conscious world: Lucchese, Dunn, Bond, Rios, Mercedes, and Dor-sey. There is some disagreement about where the middle category stops and the masters take over, but there is no argument over the quality of the boots. Prices in this category rarely fall below $200.

The Larry Mahan Collection is warming up a bid to enter the top category, Mahan says, with a new line featuring an expanded selection for women.

The master designer of the industry is Sam Lucchese. Lucchese and his family have been making boots in San Antonio since 1883. His clients have included Gene Autry, Audie Murphy, Bob Hope, John Denver, and of course, John Wayne. Tex-ans John Connally, Dolph Briscoe, and Leon Jaworski all swear by Sam’s creations, as did Lyndon Johnson.

Lucchese’s factory turns out 80 pairs of off-the-rack boots a day. But the ready-mades do not compare to Sam’s custom-made, one-of-a-kind boots produced for about three thousand steady customers whose feet are on file in the form of wooden lasts. A first-time customer usually has to wait twelve to fourteen months for delivery and the boots are likely to cost at least $500 when they arrive ($1200 for aardvark skin).

To start, Lucchese takes at least eight tape measurements for custom boots. Next, pencil outlines are made of both feet to determine appropriate length and width. An ink print shows the points at which the bottom of the foot touches the ground. Next, the shape of the top of the foot, a critical measurement, is taken with a gauge. Finally, the pattern for the boot is cut from a wooden last, ground to the shape of the foot.

“We still get requests for fancy boots from show people” – the “Rhinestone Cowboy Syndrome” he calls it – “but our best sellers these days are the plain boots. Politicians have always preferred a simpler boot. Connally always liked plain boots, out of alligator when we are able to get it,” Lucchese says.

The Lucchese Company was bought out by Blue Bell (maker of Wrangler western wear) a few years ago, but the line retains Lucchese’s name, and, retailers say, quality. Lucchese was on the Blue Bell staff until 1978, when he left and joined Tony Lama, where he now holds two titles: national director of sales and merchandising, and director of research and development.

Lucchese is adamant on one point that brings him into contention with many custom bootmakers. The use of machines for certain parts of the bootmaking process makes the boots better, he says. “The machines do what they do better than people can do it.” His Sicilian grandfather brought the first end-seam machine to Texas in 1810. Today, Lucchese says machines have improved the quality of boots. “Is it better to use a needle and thread when you can use a sewing machine? The only people who say handmade is better are people who don’t have the equipment. They’re making excuses.”

He does concede one point. “The custom bootmaker has one advantage, only one. All feet that measure 10 inches in a given spot are not the same shape. If he does his job, he may be able to fit some people better. But you’re only talking about 15 percent of the people whose feet don’t fall within the normal categories.”

Murl Jackson, who makes boots by hand, owns Jackson Boot and Saddle which he operates out of the bunkhouse of his ranch near Steamboat Springs. A Colorado native who was a wrangler for Republic Studios in Hollywood in the late 1940’s, Jackson made his first pair of boots in 1938. “I charged $15,” he said. Now he makes about 100 pairs a year – all custom for ranchers, bankers, friends, and businesspeople. Most of his customers are friends from Texas and Colorado. His work boots average $85 to $100 a pair. Exotics are priced as high as $300. Unlike Lucchese, he is certain handmade is best.

“I’ll build whatever the customer wants,” he said, adding that Texans like the “basics in natural colors.” In making a boot, Jackson notes the customer’s weight, occupation, and the length and arch of each foot.

There is more difference between a cowboy boot and an ordinary shoe than even a close glance can show because the two most important features of a boot – support and fit – can’t be seen.

Good boots are made entirely from leather, except for a rubber heel cap and a steel shank in the boot’s arch which is covered by a leather shank filler. Wooden pegs and brass nails keep the shank in place in top brand boots. According to boot people, the resulting support is unmatched by any other type of footwear. The heel can make a difference, too. A standard walking heel – about one and one-fourth inches high – puts the weight on the ball of the foot and improves posture.

A properly fitted boot will give its wearer comfort and support for the life of the boot. With a custom order, some retailers take many measurements of a customer’s foot. A properly fitted boot will, when broken in, conform to its wearer’s foot as if it were molded only for him. A bad fit can’t be overcome.

Try the boots on with the type of sock you will normally wear with them. A well-fitted boot should be comfortable from the beginning. There should be plenty of toe room and a little slippage in the heel. The instep should fit snugly. As you wear your new boot, the moisture from your skin and the flexing of the leather will shape it to your foot. According to the experts, “A boot will fit like a deerskin glove once it’s broken in.”

Take a dry cloth and brush your boots three or four times a day. When your boots get really dirty or wet, use saddle soap on them. Use a clean, wet sponge or a brush. Rub on and off. Then, while your boots are still wet, apply a coat of leather conditioner to retard drying and hold the natural oils in the leather. For a polish, try Propert’s or Meltonia shoe polishes since they penetrate well. Stay away from the liquid polishes since a lot of them contain turpentine that plays hell with the leather.

Use a color of polish that’s a little darker than the boot because sunlight and water bleach the leather. You can put silicone on the boots to help protect them against snow, ice, and salt. Use the cleanest, whitest silicone on the boots to help protect them. The yellow stuff has harsh petroleum distillates in it.

If you tear the leather, try to put the torn part back down into the cut and seal it in place with rubber cement. Then use the nearest matching color of wax you can find.

Boots can be a cachet. Regular boot-wearer Jack Richardson, for one, isnot sure he wants to see a vastnumber of Dallas men suited up andstalking around town in fancy cowboyboots. “It’s a distinguishing look,” hesays, “In a sense a man should earn theright to wear boots under a businesssuit.”

Related Articles

Arts & Entertainment

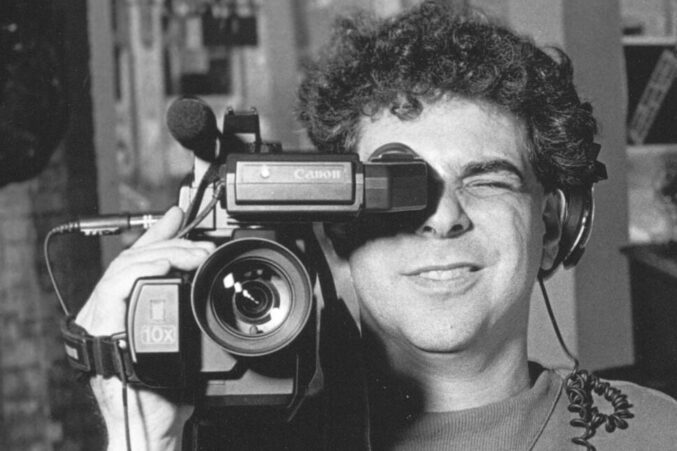

VideoFest Lives Again Alongside Denton’s Thin Line Fest

Bart Weiss, VideoFest’s founder, has partnered with Thin Line Fest to host two screenings that keep the independent spirit of VideoFest alive.

By Austin Zook

Local News

Poll: Dallas Is Asking Voters for $1.25 Billion. How Do You Feel About It?

The city is asking voters to approve 10 bond propositions that will address a slate of 800 projects. We want to know what you think.

Basketball

Dallas Landing the Wings Is the Coup Eric Johnson’s Committee Needed

There was only one pro team that could realistically be lured to town. And after two years of (very) middling results, the Ad Hoc Committee on Professional Sports Recruitment and Retention delivered.