Craftsmanship is something we associate with lost arts, like stained glass and woodcarving, not with high technology, stressed concrete,and microcircuits. But the machine age still needs craftsmen, people who do marvelous and intricate things with that most essential of tools, the human hand. Dallas owes much of its success to technical skills in fields such as aviation, medicine, and electronics; and like all city dwellers, Dallasites depend on technology to keep our traffic flowing, our gas and water pumping, our circuits humming. On the next few pages are some craftsmen who help us do just that.

J. Fred Frakes has been in the aviation business since 1942, when he became a bush pilot in Alaska. “I started out to learn to fly as a hobby. After two lessons I realized I couldn’t afford it, and decided to make aviation my life’s work.” The principal business of Frakes Aviation is converting piston-engined planes to turbine power for greater carrying capacity and higher cruising speed. “But we do a lot of other work – cabin pressurization, electrical system, air-conditioning, interiors. I can do every job myself, though my employees work faster. If something doesn’t work right we fix it. One airplane we convert to turboprop is the Ag-Cat, an agricultural airplane. Grumman has been building them for twenty years, and they all have tail wheels that shimmy. We finally fixed that this week.” Frakes’s power plant conversions involve designing and building hundreds of new parts. “I do most of the design work myself, along with an engineer, Bob Hillberg. Quite often we build the prototype ourselves. We don’t use a design board; we go from the idea to simple sketches to a prototype. I designed an autofeather system late one night on a brown paper lunch bag.”

Kirby Metcalfe came to Fort Worth in 1973 from Cadillac, Michigan, where he had taught art in a high school. In Fort Worth he went to work for Century Manufacturing, learning to make wood patterns for objects to be produced in plastic or fiberglass. “I learned to make wood objectswithin a tolerance of a few thousandths of an inch; where parts fit together, you work to zero tolerance. Because wood shrinks and swellsat every change in the weather, that’s pretty difficult to achieve.”

After two years, he went back into graphic arts. “With patterns, it doesn’t matter how they look, just how they feel. I started drawing cartoons on the patterns I made to surprise the customers – I figured then it was time to get back into graphics.” He now works at the Dallas Public Library, designing and building exhibits; when he needs to use a wood shop, he’s welcome at Century. Kirby built the pattern for the City of Dallas logo that was used in the groundbreaking ceremony for the new library (shown); it’s made of birch plywood and signboard.

Mary Tobleman began learning to use the electron microscope nine years ago as a senior at UT Austin; at that time, she thought it would be a valuable research tool for the career she planned as a veterinarian. Marriage and a child made veterinary school impractical, but Tobleman’s part-time job as an electron microscope technician allows her to participate in research and still spend time with her 18-month-old daughter. “My current project is to look for structural characteristics associated with the ability of cultured rat-liver cells to cause tumors when they’re injected into live rats. I take the cells, fix them, embed them in plastic, slice sections 500 angstroms [2 millionths of an inch thick with a diamond knife in a microtome, photograph them at magnifications up to 50,000 diameters in the E.M., and develop the photographs. The procedure is quite lengthy, and it’s not until you look at a preparation in the microscope that you find out if you did everything right.”

Fred Kennedy brought the art of scientific glass blowing to Dallas in 1956. Two years earlier, he had moved to New York from England, where he hadlearned his craft with the Rank TV organization, making then-novel picture tubes. Unable to find satisfactory work in New York (he spent a year changing tires for Firestone), he signed on with a small electronics company on Levee Street. “At that time there were no other glass blowers in town, just some neon-benders.” In 1957 he began doing contract work for the research division of Texas Instruments. Finally he was hired full time, and even set up an apprentice program, which he still supervises. “In scientific glass blowing, the pieces must be made to fit together precisely, often light-tight and able to withstand high pressures. When you’re working it it’s a bit too hot to measure, so you develop a pretty good eye. Because it’s very pure and nearly inert, glass is the best container for doing chemistry in, like growing semi-conductor crystals. Of course glass does break, but we don’t mind too much; that gives us built-in job security.”

Wallace Lutes went to work for Chance Vought in Grand Prairie in 1956, right out of high school; there he learned machining under the tutelage of two elderly Germans. “I still don’t know why they bothered to train me; I didn’t know anything.” After 16 years with Vought (later LTV), he tired of the periodic layoffs endemic to the aircraft industry, and came to work for the physics department at UT Arlington. “I make equipment for experiments with lasers, radiation, and low temperature physics, among other things. A lot of stuff has to aintain close tolerances under very high pressures and extreme temperatures – some of it in liquid helium. Working here, I’ve always got a new problem. It’s not the money that keeps me here; you could be the best machinist in the world and not earn $20,000 a year..But the work is interesting. I asked them if they were going to give me a degree; they said maybe after ten years.”

Bill Davis learned electronics as a radar technician in the Navy. After mustering out, he went to work for LTV, working on radar equipment and then flight simulators. Davis got interested in computers, and eventually went to work as a systems engineer for Scientific Controls, which has since gone out of business. Five years ago he started his own company, whose clients include Texas Instruments (“It’s cheaper for them tohire us to maintain the small computers that control their production lines than to do it themselves”) and Texas Stadium. “We maintain their computer controlled Scoreboard, and are contractually obligated to be there for every game – the only time something breaks is when it’s in use. Part of the job is just watching for burnouts the 9600 incandescent bulbs that light the main board.”

Related Articles

Business

New CEOs Appointed at Texas Women’s Foundation and Dallas Area Habitat for Humanity

Plus: Former OpTic Gaming CEO Adam Rymer finds new e-sports post, Lynn Pinker Hurst & Schwegmann hires former Mary Kay chief legal officer, and more.

By Celie Price and Layten Praytor

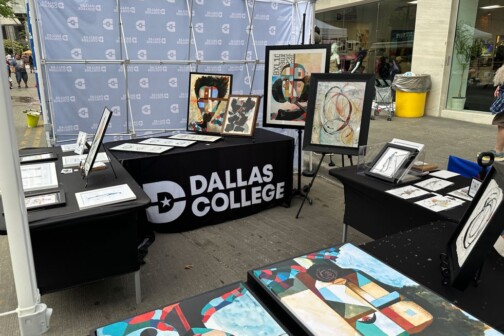

Arts & Entertainment

Dallas College is Celebrating Student Work for Arts Month

The school will be providing students from a variety of programs a platform to share their work during its inaugural Design Week and a photography showcase at the Hilton Anatole.

By Austin Zook